Composite Materials

Composite materials are formed by combining two or materials to produce a new material with improved properties such as greater strength and flexibility. Composite materials generally contain both a fibrous reinforcement and a binding matrix.

Analysis of the proportion of reinforcement, matrix and extraneous elements such as pores or faults is an essential element of characterizing composite material. The Image-Pro Composite Materials protocols divide this process into a series of easy steps and allows analysis of large volumes of data in complex formats as well as the analysis of multiple folders of images with little to no image analysis experience.

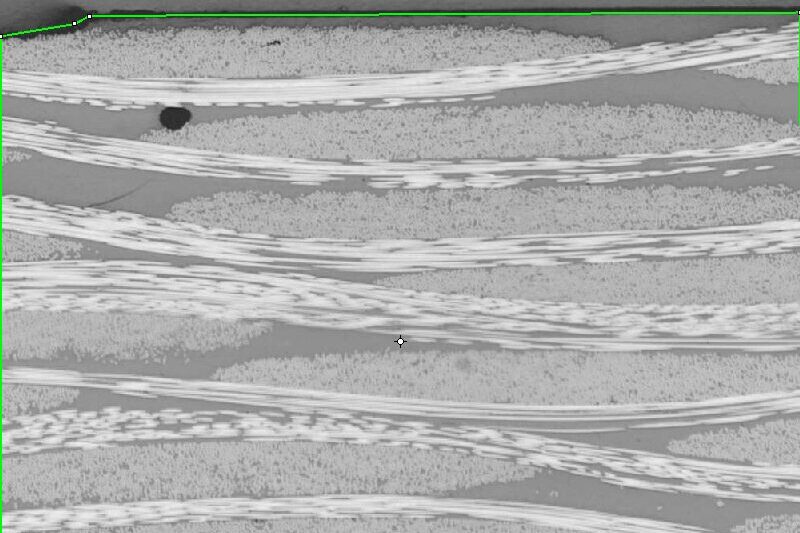

Techniques: Brightfield

How it works

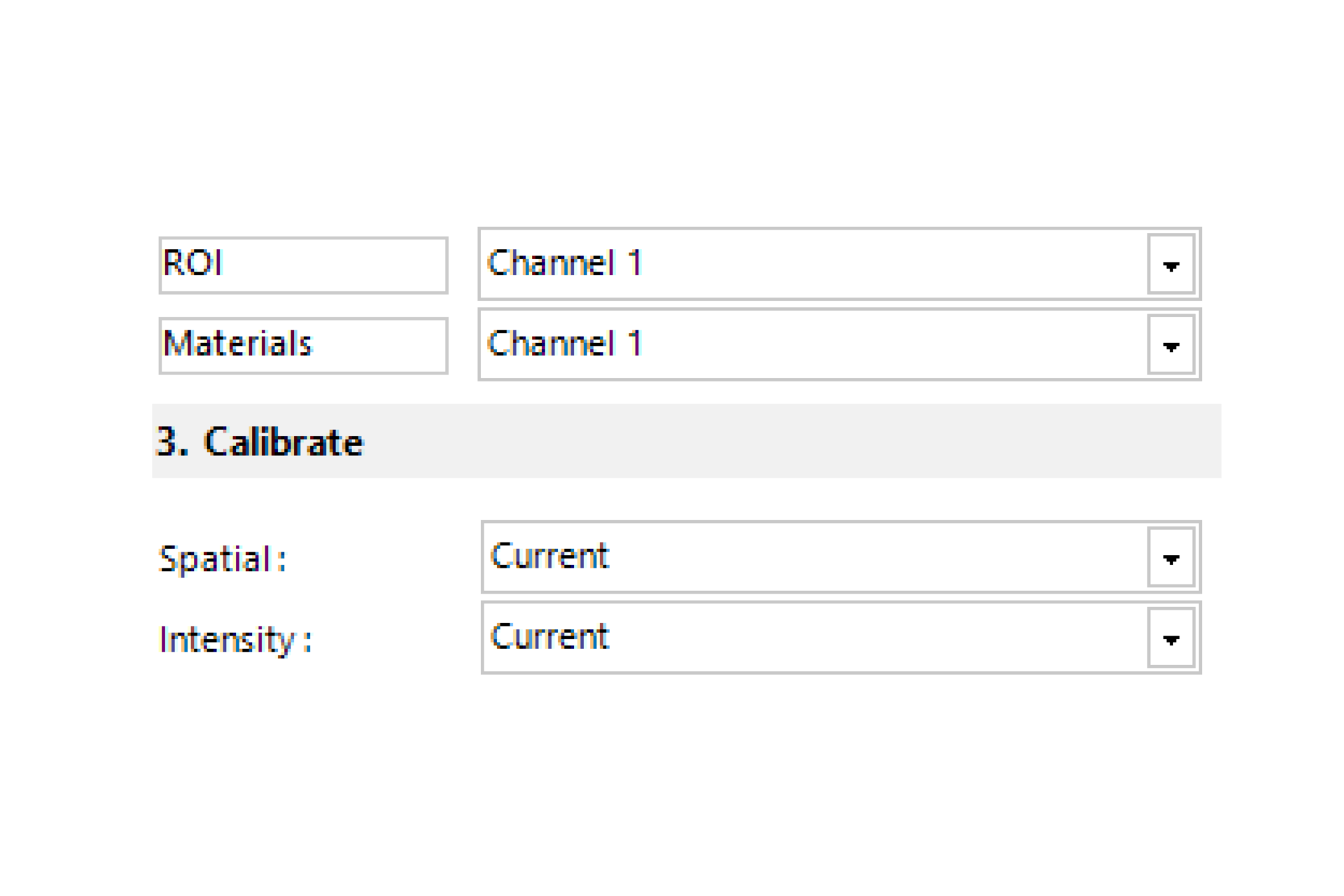

Select Channel

Select the channel that contains the composite material and apply calibrations.

Separate from Background

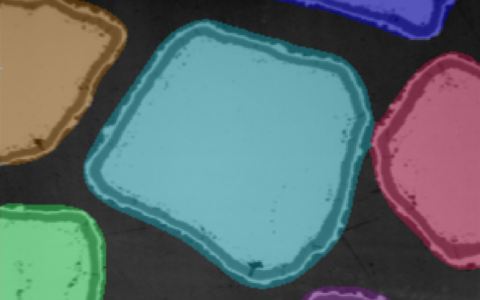

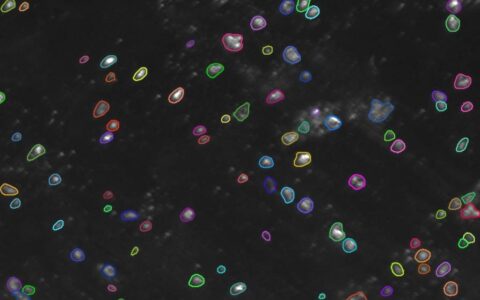

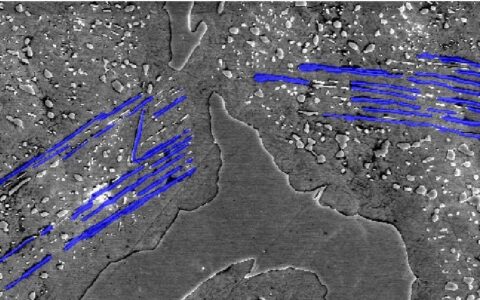

Apply a region that separates the composite material from the background.

Measure

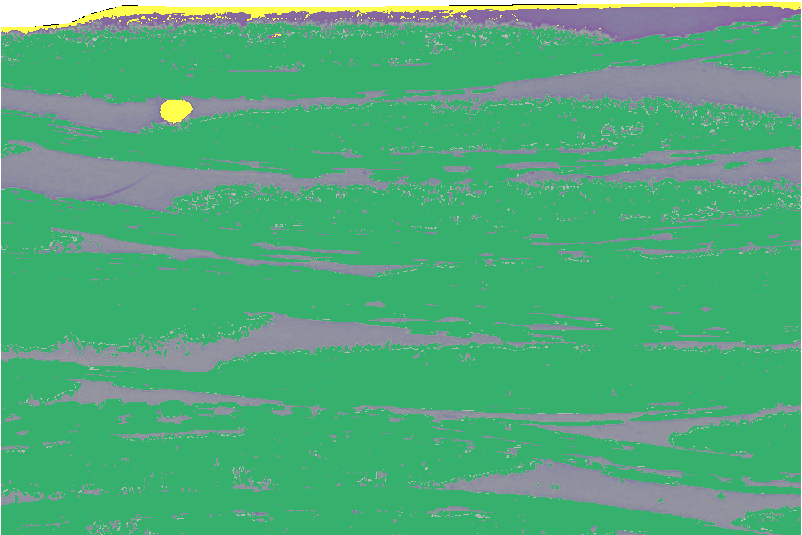

Measure the area of reinforcement fibers, matrix, and other elements using machine learning or a deep learning model.

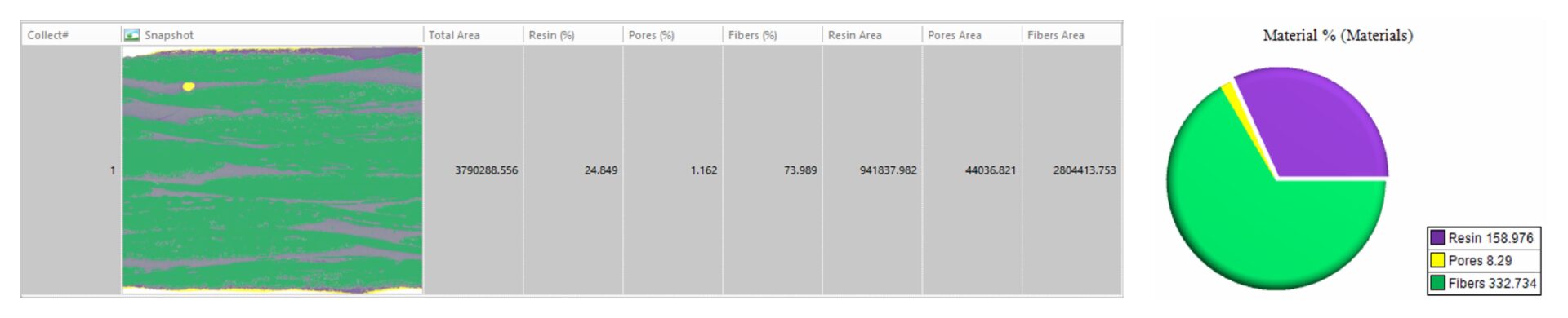

Quantitative results

Automatically generate tables, heat maps, charts and even complex bespoke reports.

Measurement parameters supported

- • Matrix Percentage

- • Fiber Percentage

- • Pore Percentage

- • Resin Area

- • Fiber Area

- • Pore Area

- • Custom user-defined measurements

Solution requirements

Required Modules

Base

2D Automated Analysis

Materials Protocol Collection

Composite Materials Protocol

Recommended Package

Literature spotlight

- Feng, X., & Yu, Z. (2024). Synthesis of Ce-La-Pr/Mn-O Ternary Oxide Composites via Co-Precipitation and Synergistic Photocatalytic Degradation of Cr (VI). Water, 16(8), 1178.

- Wang, S., Xie, F., & Wu, X. (2024). Effect of SiC Contents on Wear Resistance Performance of Electro-Codeposited Ni-SiC Composite Coatings. Coatings, 14(9), 1224.

- Wang, J., & Yang, Z. (2024). The Interfacial Reaction Traits of (Al63Cu25Fe12) 99Ce1 Quasicrystal-Enhanced Aluminum Matrix Composites Produced by Means of Hot Pressing. Coatings, 14(11), 1411.