Fiber Thickness

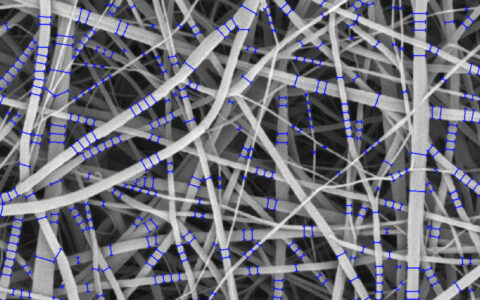

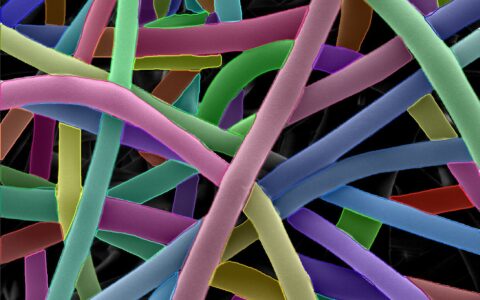

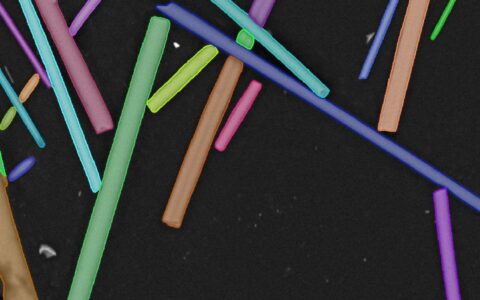

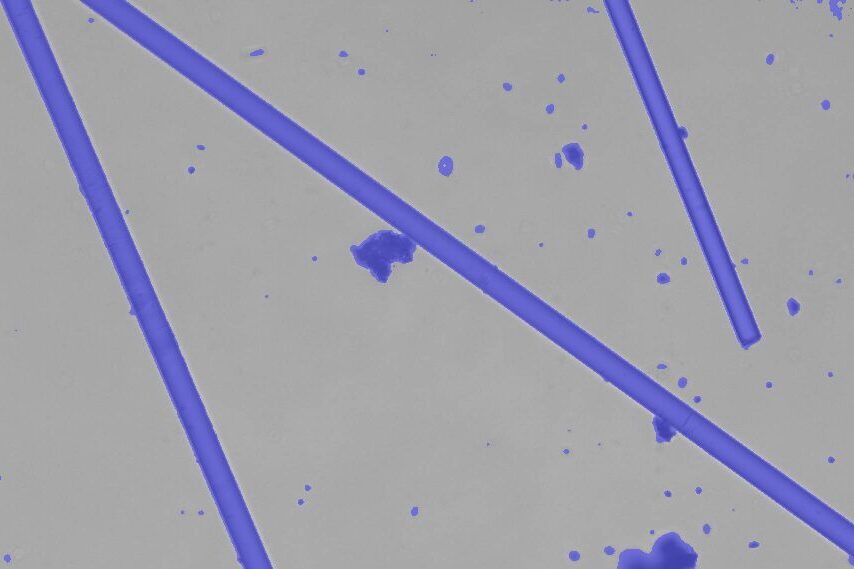

The ability to precisely measure fiber thickness (diameter) is crucial for quality assurance in the production of electrospun fibers, glass, ceramics, and similar materials. However, segmenting densely packed fibers within a field of view can often be a challenging and time-consuming task.

The Image-Pro Fiber Thickness protocol streamlines this process with a series of easily configurable steps, enabling efficient analysis of large datasets with minimal image analysis expertise. Individual fibers can be segmented using pre-trained deep learning models, machine learning, or a custom algorithm, ensuring accurate and reproducible results.

Techniques: Brightfield

How it works

Select Channel

Select the channel that contain fibers.

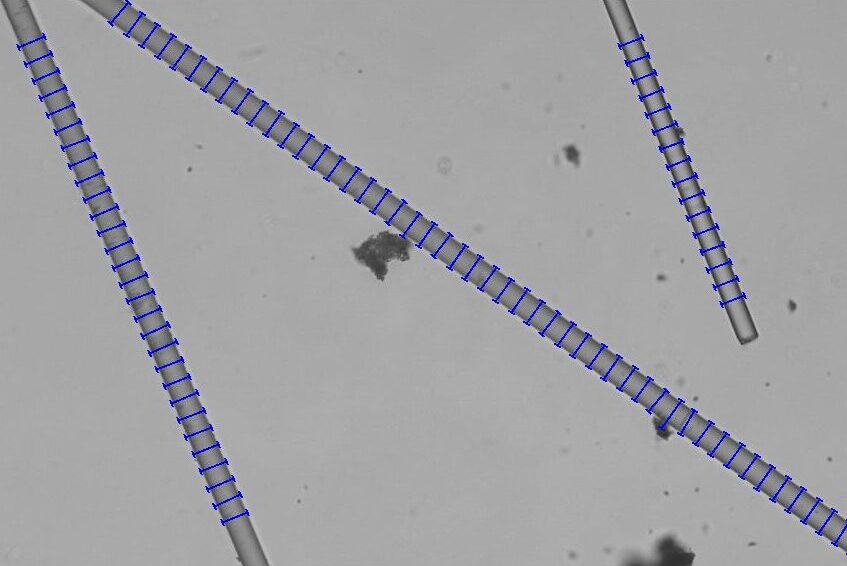

Set Diameter

Set the diameter for a pre-trained deep learning model, or set settings for machine learning or a custom algorithm.

Measure

Automatically measure fiber thickness.

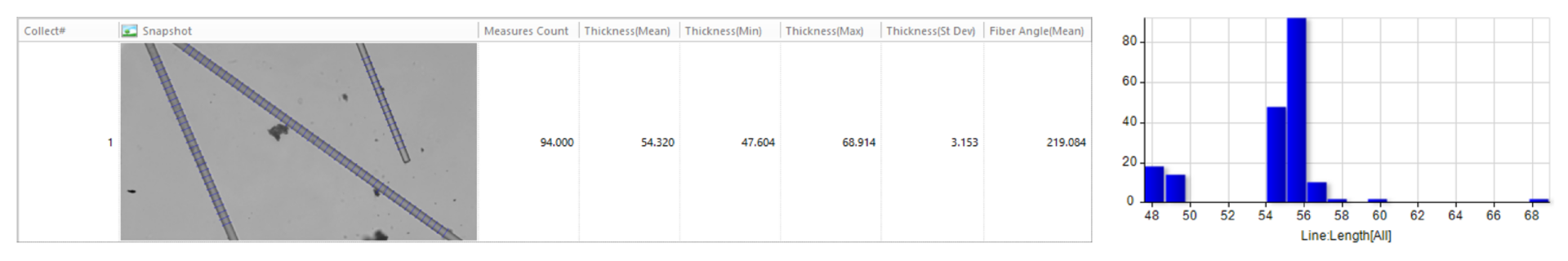

Quantitative results

Automatically generate tables, heat maps, charts and even complex bespoke reports.

Measurement parameters supported

- • Mean Thickness

- • Minimum Thickness

- • Maximum Thickness

- • Standard Deviation

- • Mean Fiber Angle

- • Custom user-defined measurements

Solution requirements

Required Modules

Base

2D Automated Analysis

Materials Protocol Collection

Fiber Thickness Protocol

Recommended Package

Literature spotlight

- Jiang, L., Jiang, Y., Stiadle, J., Wang, X., Wang, L., Li, Q., ... & Turng, L. S. (2019). Electrospun nanofibrous thermoplastic polyurethane/poly (glycerol sebacate) hybrid scaffolds for vocal fold tissue engineering applications. Materials Science and Engineering: C, 94, 740-749.

- Xiao, Y., Sakib, N., Yue, Z., Wang, Y., Cheng, S. I., You, J., ... & Zhu, G. (2020). Study on the relationship between structure parameters and filtration performance of polypropylene meltblown nonwovens. Autex Research Journal, 20(4), 366-371.

- Zhang, L. Y., Tsuzuki, T., & Wang, X. G. (2010, October). Preparation and characterization on cellulose nanofiber film. In Materials Science Forum (Vol. 654, pp. 1760-1763). Trans Tech Publications Ltd.