Fiber Separation (EM)

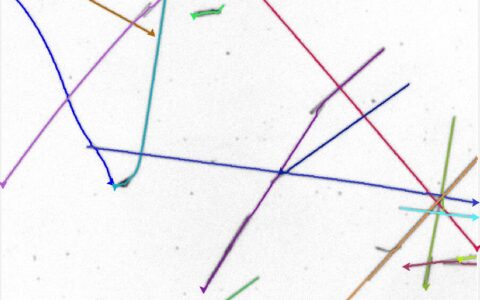

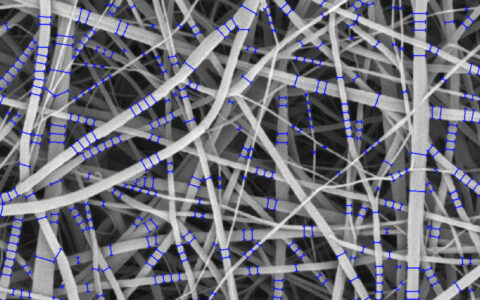

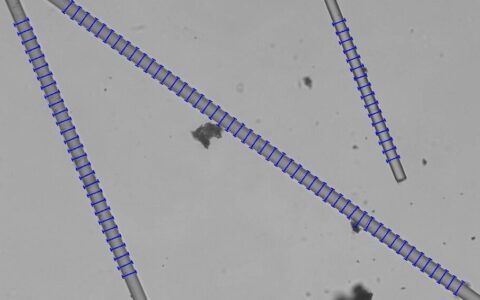

Accurately analyzing the length and number of fibers in a field of view can be challenging due to overlapping structures, which often make the process time-consuming and complex. Overlapping fibers can obscure important details, complicating segmentation and reducing the reliability of measurements.

The Image-Pro Fiber Separation protocol simplifies this task by breaking the workflow into manageable steps. It automatically separates overlapping fibers with precision, allowing users to extract accurate measurements such as fiber length, count, and orientation. Designed for efficiency, the protocol supports high-throughput analysis of large datasets, including complex formats like multi-well plates or multiple image folders, all with minimal image analysis expertise required.

Techniques: SEM, TEM

Solution Requirements

Required Modules

Base

2D Automated Analysis

Materials EM Protocols Collection

Fiber Separation (EM)

Recommended Package