Fiber Thickness

(EM Ceramic/Glass)

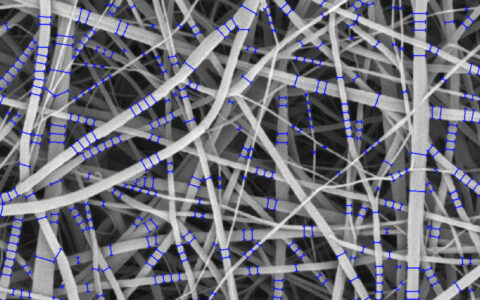

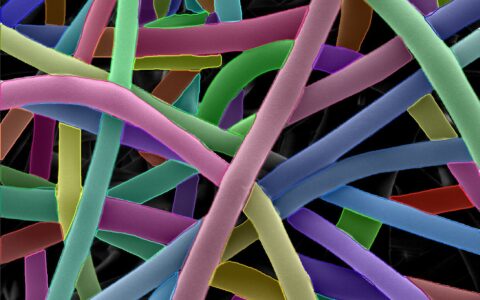

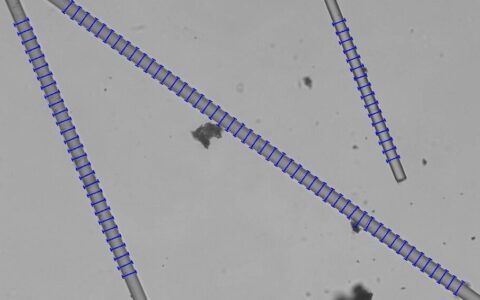

The ability to precisely measure fiber thickness (diameter) is crucial for quality assurance in the production of ceramics, glass, electrospun fibers, and similar materials. However, segmenting densely packed fibers within a field of view can often be a challenging and time-consuming task.

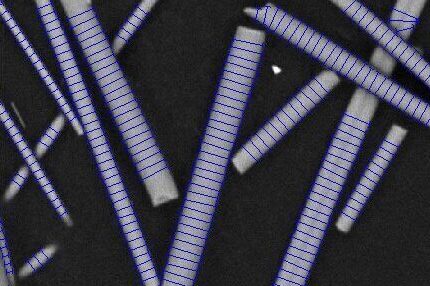

The Image-Pro Fiber Thickness (EM Ceramic/Glass) protocol streamlines this process with a series of easily configurable steps, enabling efficient analysis of large datasets with minimal image analysis expertise. Individual fibers can be segmented using pre-trained deep learning models, machine learning, or a custom algorithm, ensuring accurate and reproducible results.

Techniques: Brightfield, SEM, TEM

How it works

Select Channel

Select the channel that contains fibers.

Set Diameter

Set the diameter for a pre-trained deep learning model, or set settings for machine learning or a custom algorithm.

Measure

Automatically measure fiber thickness.

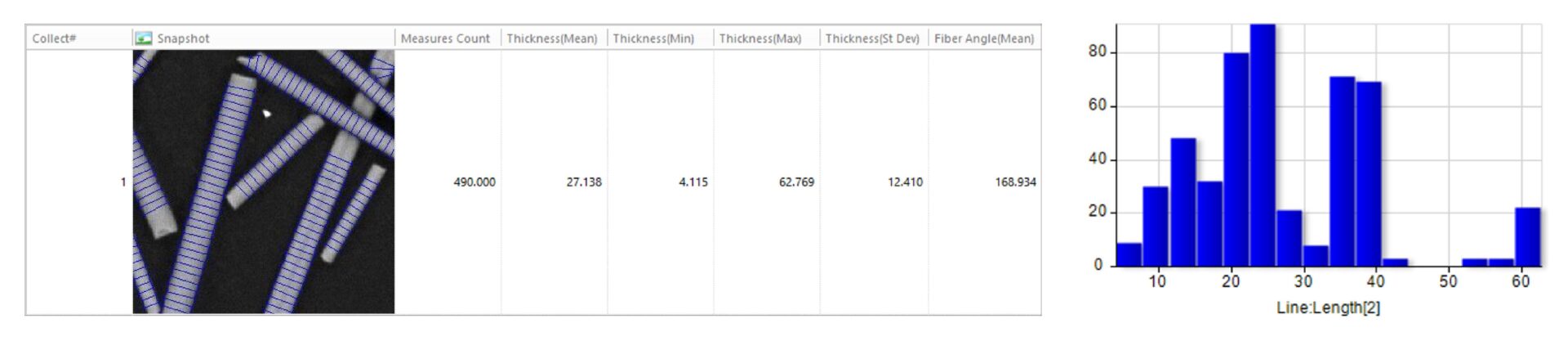

Quantitative results

Automatically generate tables, heat maps, charts and even complex bespoke reports.

Measurement parameters supported

- • Mean Thickness

- • Minimum Thickness

- • Maximum Thickness

- • Standard Deviation

- • Mean Fiber Angle

- • Custom user-defined measurements

Solution requirements

Required Modules

Base

2D Automated Analysis

Materials EM Protocols Collection

Fiber Thickness (EM) Protocol

Recommended Package

Literature spotlight

- Ferreira, T. R. M., Lechtman, M. D. A., Dias, F. L., & Silva, A. B. D. (2022). Effect of hollow glass microspheres addition on density reduction and mechanical properties of PA6/glass fibers composites. Polimeros, 32(1), e2022001.

- Zhou, N., Xu, B., Zhou, Z., Qu, L., Wang, Y., Han, W., & Fang, D. (2023). Lightweight quasi-layered elastic fibrous porous ceramics with high compressive stress and low thermal conductivity. Journal of Materials Science & Technology, 143, 207-215.