Grain Size (ASTM E112

Segment Method)

Grain size analysis is crucial for optimizing mechanical properties, ensuring quality, and predicting performance. Grain size affects strength, hardness, ductility, and corrosion resistance, playing a key role in failure analysis, weld integrity, and industry compliance (e.g., ASTM E112). Controlling grain structure improves wear resistance, prevents defects, and enhances reliability in aerospace, automotive, and structural applications.

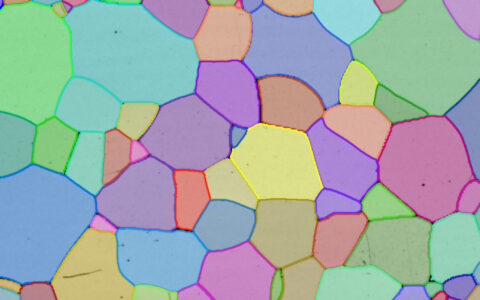

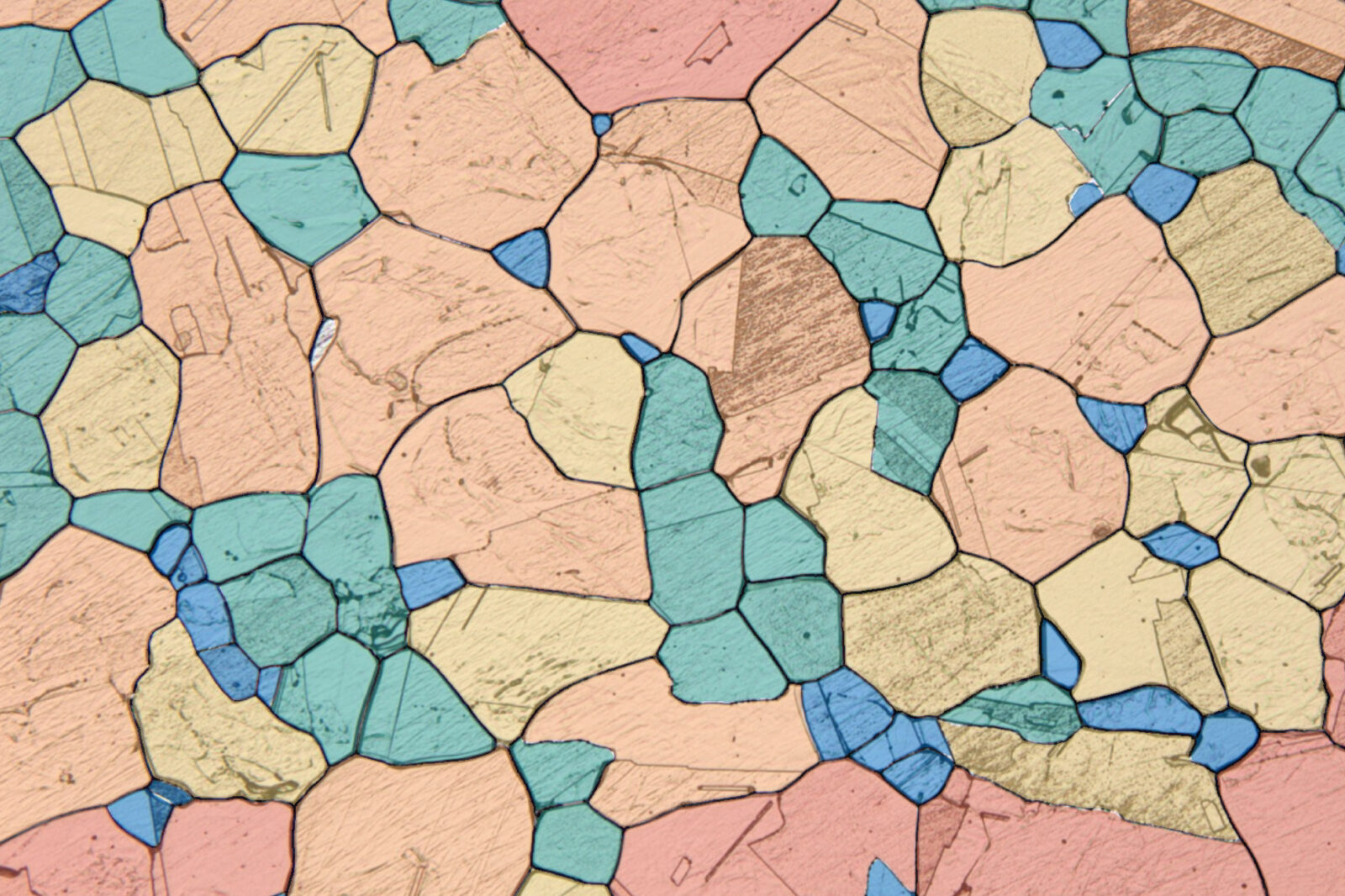

The Image-Pro Grain Size Protocol streamlines measurement via boundary detection or direct grain counting using AI-driven segmentation. Its structured workflow ensures accuracy, reproducibility, and ease of use, enabling efficient large-scale analysis—even for users with little to no image analysis experience.

Techniques: Brightfield

How it works

Select Image

Select your grains phase image and check that the correct calibrations are applied.

Set Diameter

Set an approximate grain diameter (direct detection) or configure a custom algorithm to detect grain boundaries.

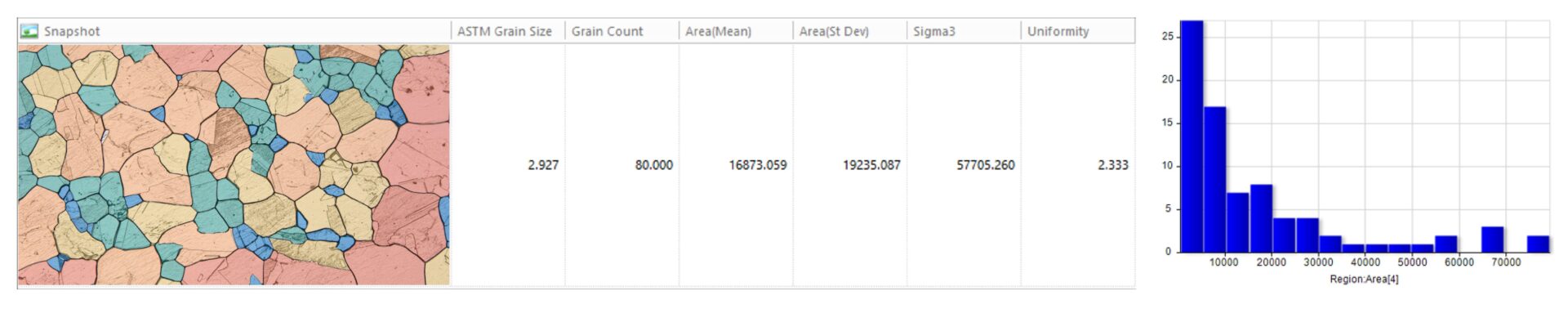

Measure

Count and measure individual grains.

Quantitative results

Automatically generate tables, heat maps, charts and even complex bespoke reports.

Measurement parameters supported

- • ASTM grain size

- • Grain count

- • Grain area (mean)

- • Grain area - standard deviation

- • Sigma3

- • Uniformity

- • Custom user-defined measurements

Solution requirements

Required Modules

Base

2D Automated Analysis

Materials Protocol Collection

Grain Protocol

AI Deep Learning

Materials Models

Versatile Grains Model

Recommended Package

Literature spotlight

- Dziubińska, A., Surdacki, P., & Majerski, K. (2021). The analysis of deformability, structure and properties of AZ61 cast magnesium alloy in a new hammer forging process for aircraft mounts. Materials, 14(10), 2593.

- Jing, T., Ning, Y. T., Liu, H. L., Yang, B., & Chen, Y. (2023, March). Effect of Vanadium on Austenite Grain Refinement and Martensite Structure. In 6th International Conference on Advanced High Strength Steel and Press Hardening (ICHSU 2022) (pp. 36-41). Atlantis Press.

- Li, Y., Huang, X., Ji, H., Li, Y., Wang, B., & Tang, X. (2021). Study on Dynamic Recrystallization Models of 21-4N Heat Resistant Steel. Archives of Metallurgy and Materials, 66.